Vloerverwarming infrezen bij Fermacell / Estrich / Knauf / Gipsvezelplaten

Bezoek de showroom

Uipkes Wood Flooring can completely take care of the actions of removing the 'old' floor, installing the Fermacell / Estrich / Knauf / Gypsum fiber boards subfloor, installing the underfloor heating and installing the beautiful new wooden floor that you have bought with us. You can also have underfloor heating installed as a separate service from us.

We can take care of the organization of all work and therefore completely relieve you of your worries. From the removal of the existing floor until the moment that the furniture can be placed back on the new wooden floor.

Removal of the existing floor

The installation of the Fermacell / Estrich / Knauf or Gypsum Fiber Board subfloor is used if the underfloor heating cannot be milled into the existing screed floor. This usually concerns if a home has a wooden screed floor.

We will professionally remove and dispose of the existing finishing floor such as PVC, laminate or existing wooden floor. We will check the screed for broken or creaking parts and secure these before installing the Fermacell / Estrich / Knauf or Gypsum Fiber Board subfloor.

Existing radiators and convector ducts

When installing underfloor heating , existing radiators and convector ducts can be closed off and removed. Disconnecting and removing existing radiators and convector ducts must be carried out by a plumber. Uipkes can cover the old convector pits during the preparation of the floor, creating a flat, solid surface for installing the Fermacell/ Estrich/ Knauf/ Gypsum fiber boards subfloor.

If necessary, Uipkes wooden floors can supply a plumber who will take care of this work.

Installing the Fermacell / Estrich / Knauf / Plasterboard subfloor

After the existing finishing floor has been removed and checked for defects, we install the Fermacell/ Estrich/ Knauf/ Gypsum fiber boards subfloor. The plates measure approximately 500 mm wide and 1500 mm long and have an overlapping bottom and overhang on which the glue is applied.

Edge strips are placed along the walls to prevent sound transmission. The Fermacell/ Estrich/ Knauf/ Gypsum fiber boards are placed on top of each other for a tight fit and secured with screws to ensure a good bond of the glue. The plates are placed brick by block for correct stress distribution for the wooden floor. After the glue has hardened, the screws must be removed so that they do not damage the milling machine.

Bezoek de showroom

Milling the slots and installing the pipes

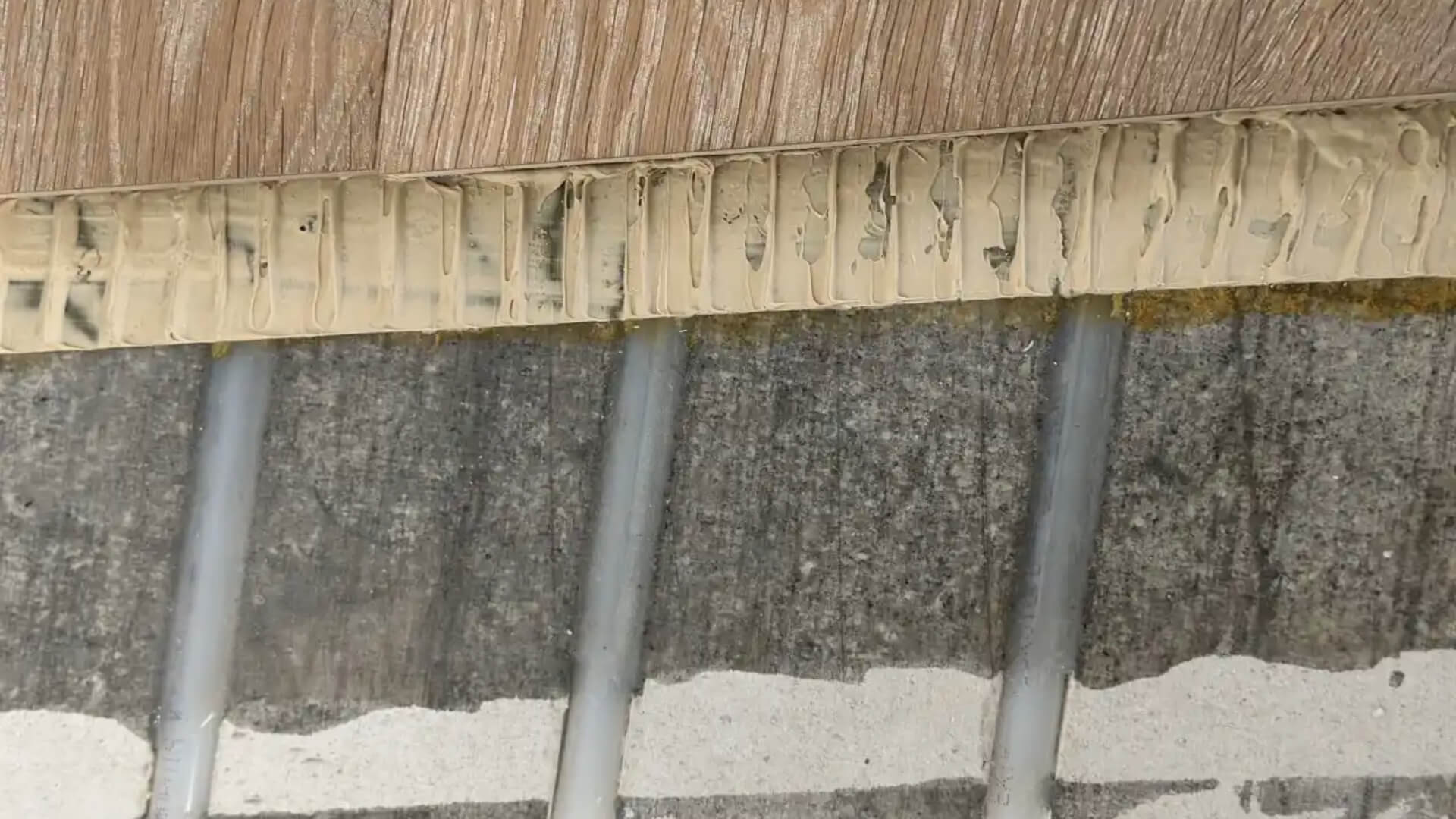

Based on a Fermacell/ Estrich/ Knauf/ Gypsum fiberboard subfloor, we mill the slots with a special floor milling machine to a depth of approximately 17 mm. The distance between the slots is milled 10-12.5 cm center to center. Milling is carried out as dust-free as possible thanks to the special dust extraction.

Plastic pipes with a width of approximately 14mm are placed in these slots. The pipes fit exactly into the slots and are therefore firmly secured. After the pipes have been installed, they are connected to the distribution station, which is placed in a central location. This is usually a stair cupboard or another central point.

If there is no supply and discharge from the boiler, a plumber must prepare this. There must also be a power point at this location. If necessary, Uipkes wooden floors can supply a plumber who will take care of this work. The distribution station can then be connected to the heating boiler supply.

Once the system has been tested, we ensure that the pipes are fixed in the bends, so that the pipes remain deep in the trench during filling. The slots are filled with an epoxy, diluted with the grinding dust or a special flexible filling mortar, which can expand and contract with the heat of the pipes. This is spread over the floor with a trowel, so that the filling is evenly distributed in the slots and the floor. gets a flat finish in preparation for the new wooden floor.

How many groups are needed for underfloor heating ?

For the number of groups, the rule of thumb of 1 group per 8-9 m2 (as main heating) can be used. The pipes are placed at a distance of approximately 10 cm from center to center.

Magazine Vol inspiratie

Magazine aanvragenTotal cost indication

For the cost indication we assume an average area of 50m2:

- The costs for removing and disposing of the existing finishing floor start from €15/m2 incl. VAT. (depending on the type of floor).

- For checking the screed floor, installing the Fermacell/ Estrich/ Knauf/ Gypsum fiber boards subfloor and edge strips, an investment of approximately €60/m2 incl. VAT must be taken into account. Based on 50m2, this amounts to an investment of approximately €3000,- incl. VAT

- The investment for milling the underfloor heating , installing the pipes, installing the distribution station, covering the slots and connecting the pipes to the distribution station amounts to an investment of approximately €3150 for a space of 50 m2. - incl VAT.

Lead time for complete package

Even though the work is extensive, the turnaround time is not too bad. Based on our example of 50m2, complete care of all work from removing the existing floor to replacing the furniture would have a lead time of approximately 7-21 days. (provided all preparatory work has been carried out)

You can maintain the following distribution:

- Removing and disposing of the existing floor, installing the Fermacell/ Estrich/ Knauf/ Gypsum fiber boards subfloor and edge strips; approx. 1 day.

- Milling the underfloor heating , installing the pipes, hanging the distribution station, connecting the pipes to the distribution station and lubricating the pipes, approximately 1 day. (if all other preparatory work has been carried out)

- Installing a new wooden floor, including colour finish: approx. 3 days .

- Drying of the color treatment: approx. 2 days.

Bezoek de showroom

-

Points of attention

- Space should be free of items.

- After removing the existing floor, check the screed for broken or creaking parts.

- Existing radiators and convector ducts must be disconnected and removed by a plumber (preparatory work).

- When installing the Fermacell/ Estrich/ Knauf/ Gypsum fiber boards subfloor, screws are used to ensure good adhesion for the glue. These screws must be removed before milling can begin to prevent damage to the milling machine.

- A supply and discharge from the heating boiler must be prepared at the position of the distribution station. There must also be a power point at this location.

- Before the wooden floor can be placed on underfloor heating , the underfloor heating must first be tested.

-

Do you want to have underfloor underfloor heating milled in?

Do you want to have underfloor heating milled in Fermacell, Estrich, Knauf, or install gypsum fiber boards or underfloor heating in a different type of subfloor ? We also offer the installation and connection of underfloor heating as a separate service. Visit one of our showrooms to coordinate the project and view our stylish oak floors .

Frequently Asked Questions

What is the advantage of underfloor heating compared to radiators?

Underfloor heating provides an even heat distribution in the room, without the presence of radiators. This ensures comfortable and pleasant heating, without cold zones or air circulation. In addition, underfloor heating uses energy more efficiently, which means it can often be cost-saving.

Can underfloor heating be installed in different types of subfloors?

Yes, underfloor heating can be installed in various types of subfloors, such as Fermacell, Knauf, Estrich or gypsum fiber boards. The type of subfloor affects the installation method and materials used.

Do I have to have my existing floor covering removed to install underfloor heating ?

In most cases it is necessary to remove the existing floor covering before the underfloor heating can be installed. This is important to ensure good adhesion and operation of the underfloor heating . Uipkes can also take care of this removal work for you.

How long does it take to install underfloor heating and install a new wooden floor?

The total lead time from removing the existing floor to replacing furniture usually varies between 7 and 14 days, depending on the surface area and preparatory work.

Installing the Estrich / Knauf / Fermacell / Gypsum fiber boards subfloor and edge strips takes approximately 1 day, milling the underfloor heating and connecting pipes takes approximately 1 day, and installing the new wooden floor takes approximately 3 days.

Can I have underfloor heating installed without buying a new wooden floor?

Yes, Uipkes offers the installation of underfloor heating as a separate service. This means that you can have underfloor heating installed without buying a new wooden floor. You can contact us to discuss the possibilities.

Are any special preparations required before the wooden floor can be placed on the underfloor heating ?

Yes, before the wooden floor can be placed on the underfloor heating , the underfloor heating must first be tested to ensure that everything functions properly. In addition, it is important that the room is free of furniture and that any preparatory work, such as checking the screed floor and disconnecting radiators, has been carried out.

- Choosing a selection results in a full page refresh.

- Opens in a new window.